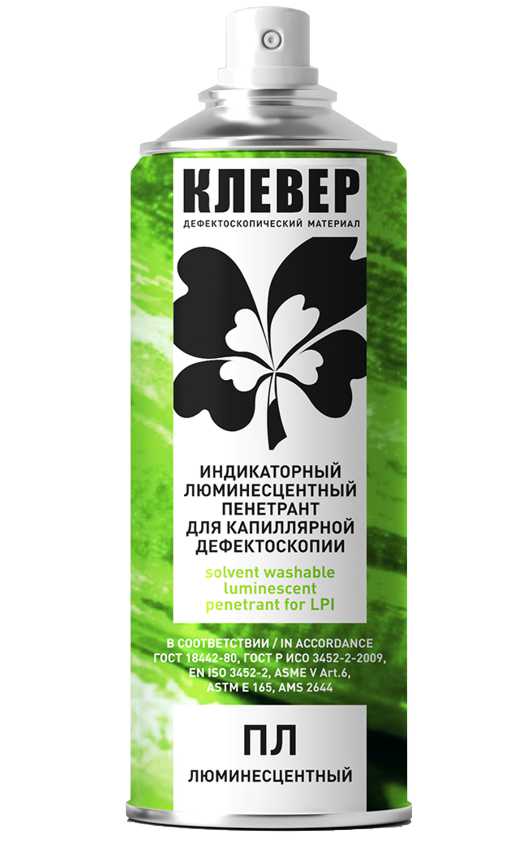

Luminescent penetrant KLEVER-PL is created from high quality domestic chemical components. It is intended for use in various types of industry for the control of surface defects of 0,5 microns and larger. Washable with water or cleaner. Used for inspection of various critical products.

Provides sensitivity of capillary control on level II and III in accordance with GOST 18442 - 80, GOST R ISO 3452-2-2009. Conforms to EN ISO 3452-2, ASME V Art.6, ASTM E 165, AMS 2644.

Method of Application:

- On the prepared cleaned and dry controlled surface from a distance of 15-35 cm apply the penetrant in a thick layer.

- After holding for 1 minute, apply a second layer of penetrant. The total time of penetrant exposure should be 5-7 minutes.

- After curing, remove excess penetrant from the surface with running water or a cloth soaked in KLEVER KL solvent.

- Check the quality of penetrant cleaning in ultraviolet light (wavelength 365nm), e.g. using the illuminators WOLNA-UV365, BRIZ-UV365 or POTOK-UV365.

- Repeat the cleaning procedure if necessary.

- Dry the surface with a dry cloth or compressed air.

- To develop indicator traces, apply KLEVER DP developer to the controlled surface.

- Incubate for 5-10 minutes and evaluate the control result in UV light (365 nm).

Manufactured in accordance with TU 20.59.59.000-011-77720383-2023. Conforms to GOST 18842-80, GOST R ISO 3452-2-2009, EN ISO 3452-2, ASME V Art.6, ASTM E 165, AMS 2644.

Distinctive features

Control of surface defects from 0,5 microns.

Penetrant is created from high quality domestic chemical components.

Package includes