127410, Российская Федерация, Москва, Алтуфьевское ш., д.41А, email: info@expertnk.ru

+7(495) 660 94 49 (многоканальный номер)

8 (800) 250 94 49 (бесплатный для регионов)

+7(495) 660 94 49 (многоканальный номер)

8 (800) 250 94 49 (бесплатный для регионов)

- Certification Of Specialists

- Laboratory Accreditation

- NDT Devices & Means

- Calibration Of NDT Funds

Corner vacuum box (inside corner) with arrow vacuum indicator gauge and valve handles (3,15x14,96 in)

- Home

- NDT Devices & Means

- Penetrating substances

- Tightness control

- Corner vacuum box (inside corner) with arrow vacuum indicator gauge and valve handles (3,15x14,96 in)

Price level: Retail

Corner vacuum box with arrow vacuum indicator gauge and valve handles. The box aims at the leak test which is based on the bubble test and is used on tee-butt and fillet welds (inside corner).

Viewing area – 3,15x14,96 in. Box rubber thickness – 0,98 in.

The vacuum box could be used for checking:

- reservoirs,

- boilers,

- pipelines,

- fuel tanks,

- coating,

- other objects with one-sided access.

Distinctive features

- Patented in-house design for convenient control and low energy consumption of the testing operator.

- Convenient system of air pumping out and in within a single push of the handle which makes the operating fast and comfortable.

- Specially designed molded rubber strip makes the contact with the inspected surface more leak-tight. It helps to reach the ultimate degree of exhaustion within the box:-0,09 MPa, which exceeds PNAE G-7-008-89 and PNAE G-7-019-89 standards for IV class leak - tightness (Rules and Norms of Nuclear Power Generation Industry)

- Operational tests showed that the leak-tightness in the vacuum box is kept for a long time (pressure decrease to -0,08 MPa during 20 min).

- It is suitable for operating with any kind of vacuum pumps.

- Valve handles basically are completed with barb connectors, but could be completed at customer’s option with a quick – detachable connector which makes in-operating vacuum box changing very fast.

Package includes

- vacuum box with arrow vacuum indicator gauge and valve handles;

- ticket (with a manual);

- package.

Certificates

Compliance with standards:

- Patent No. 2636409 dated 11/23/2017 issued by Federal Service for Intellectual Property.

Basic options | |

| Valve handles | yes |

| Vacuum gauge | yes |

Control parameters | |

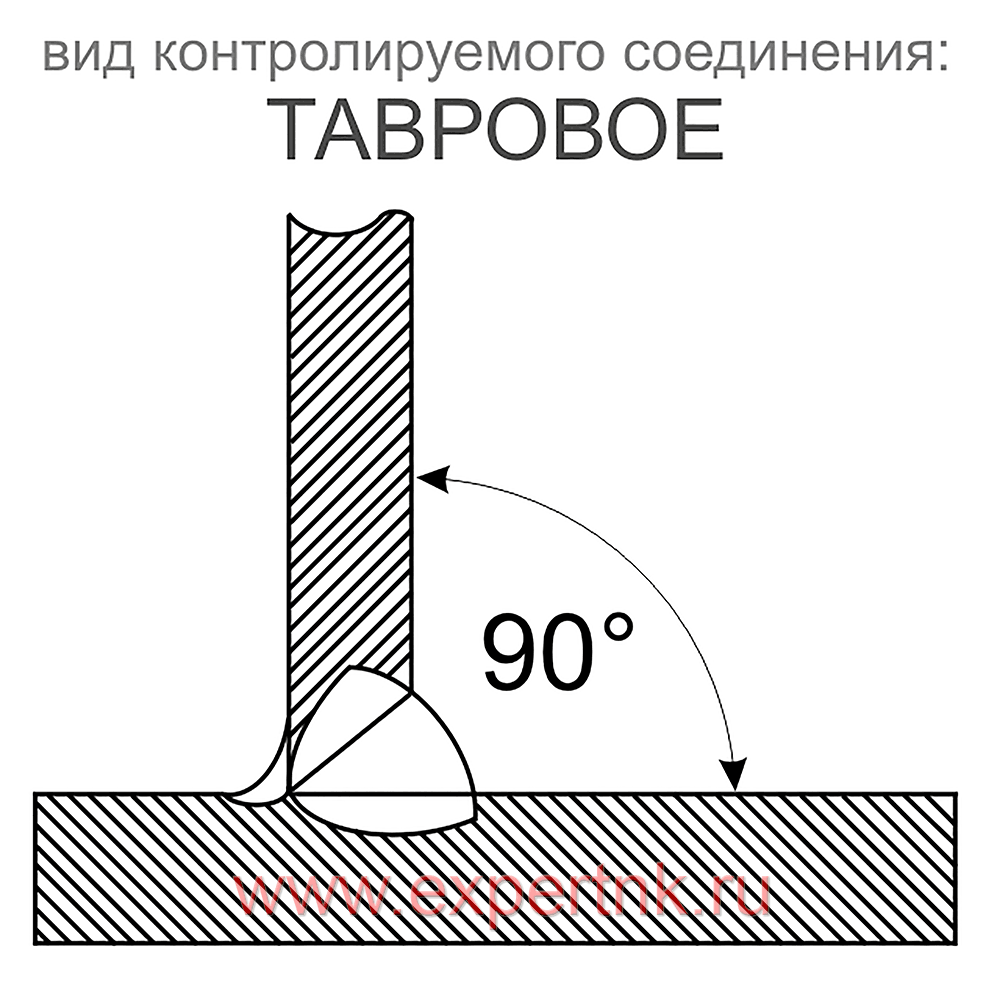

| Type of monitored connection | t-joint / inner corner |

| Viewport size, mm | 80 x 380 |

| Operating vacuum pressure, MPa | from -0,070 to -0,090 |

Dimensions and weight | |

| Width, mm | 140 |

| Length, mm | 500 |

| Rubber thickness, mm | 25 |

| Weight, kg | 1,000 |

Operating conditions | |

| Operating temperature range, °C | from -20 to +55 |

There are no reviews for this product yet.. Write the first review.

Foam-film indicator PPI-1 (canister 1 l)

Code: 75D702

Universal bubble indicator of leaks of gaseous media. Corresponds to PNAE G-7-019-89.720 руб.Into a basket

Foam-film indicator PPI-1 (canister 5 l)

Code: 73D703

Universal bubble indicator of leaks of gaseous media. Corresponds to PNAE G-7-019-89.3 120 руб.Into a basket

Call us

Have questions? Call us!

+7(495) 660 94 49 (multichannel)

8 (800) 250 94 49 (free for regions)

Copyright © 2025 "EXPERT NK" LLC. All rights reserved.

| Retail | checkout at the office; |

| Online Starter* | entry level benefits; |

| Online 1..5* | five steps: more orders - more benefits; |

| Online Wholesale* | maximum benefit; |

| Online VIP* | individual discount. |

* valid only for orders placed on the site, according to the standard templates of contracts and accounts, it is mandatory to accept the Confidentiality Conditions for the information of an individual offer